11.29.21

BUILDING CONTROLS SIMPLIFIED

Building control systems are like thumbprints—no two are the same and each one varies depending on the building elements being managed. Combining all electrical and HVAC systems into a central access point, today’s systems are more complex than ever, and there are a lot of options to choose from.

If this sounds overwhelming, it can be. But it doesn’t have to be.

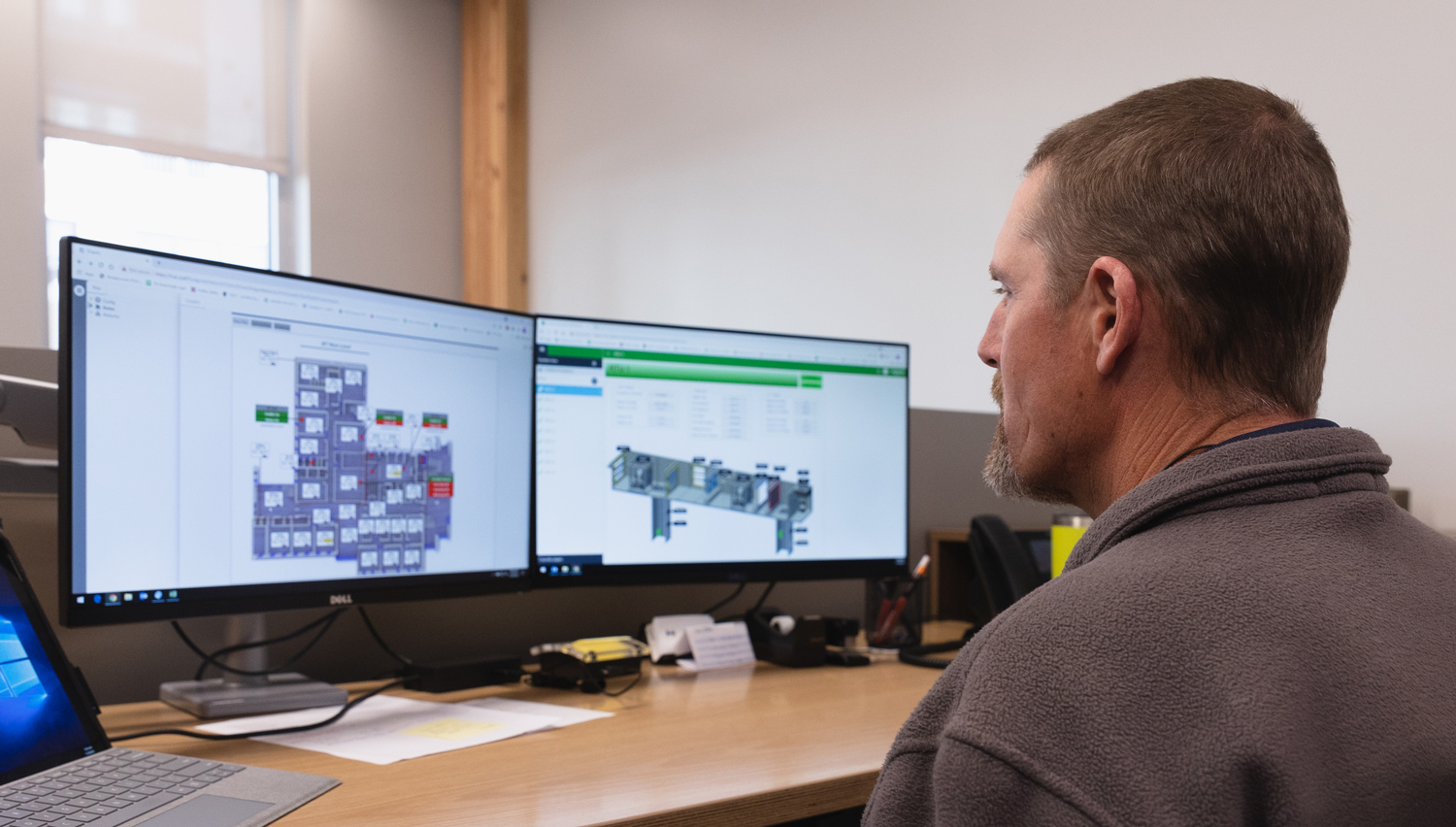

Tommy Chapin, Hutton mechanical coordinator, oversees system installations and simplifies the process for our clients and project teams. With 16 years of controls and mechanical experience, Tommy knows what the biggest roadblocks can be for each individual project. He addresses them proactively with the team before the budget or project sequencing are impacted.

“We communicate with clients and project teams from day one,” said Chapin. “We’ve had control designers in our meetings, and they’ve had an opportunity to talk about things like power to their equipment, which really helps the process stay proactive.”

“Building controls” used to refer only to a roof top unit or two. Now, in addition to HVAC, they can include the lighting controls package, total room automation (lighting control, shades and blinds, temperature), CO2 monitoring, a control strategy for the dampers, and more.

For a superintendent who is managing a schedule and teams, control system complexities would be “a lot for a superintendent to relearn on every project,” said Hutton superintendent Roby Carruth. “Tommy knows what he’s looking for in each system, and what questions to ask so we don’t hit a hard stop because something hasn’t been ordered.”

Knowledge of different systems and their logistical needs helps shape sequencing. From a superintendent perspective, it might be tempting to install the HVAC and electrical elements first and deal with controls last.

“That’s really a recipe for disaster,” said Hutton superintendent Joerg Nahrendorf, because there isn’t enough time to operate complicated equipment the way they need to be commissioned. “Having Tommy there to keep an eye on controls and remind subcontractor teams of items we need ordered and in place has been invaluable.” When it’s time to turn the facility over to our client, the systems must be 100% complete and online.

Running fiber can be another potential roadblock if not discussed early, since all of the controls are operated over the internet. “On one project, we worked with Tommy and our client’s IT department very early on to provide network capabilities,” said Nahrendorf. “We got temporary equipment from the owner that we utilized during construction and were able to have the equipment talk to the network.”

Building owners wear many hats and once a project is built, they often don’t have a point-person focused on building controls, or have little controls experience, and now have to learn a new system. Training and helping the owner get comfortable with the system is critically important. Tommy’s depth of knowledge helps smooth out the transition.

“On one school project, Tommy was able to work with the controls contractor very early on, and together they created the graphic interface specifically for the project,” said Nahrendorf. With input from school officials and previous experience with their building systems, they customized an interface that is easy for staff to use.

Clients are encouraged to log on and click through the system during the warranty period to increase their comfort level. If they have a question or concern, Tommy can log in remotely and help them resolve the issue if he has a user account.

“I try to make it as easy as possible,” Chapin said. “It’s generally a lot of quality control, looking ahead to get in front of roadblocks. I communicate with superintendents and mechanical contractors directly and try to keep things simple.”

If you have a project that needs a lot of mechanical work, we have the team and process to help you through the process.

Thank you for reading

For more information, please get in contact with Brandon Brungardt at 316.942.8855.